Solutions » Introduction to Industry-Specific Solutions »

Film Manufacturing Process Equipment »

6. Coating

|6. Coating

Film is coated with various types of solvents, depending on the application.

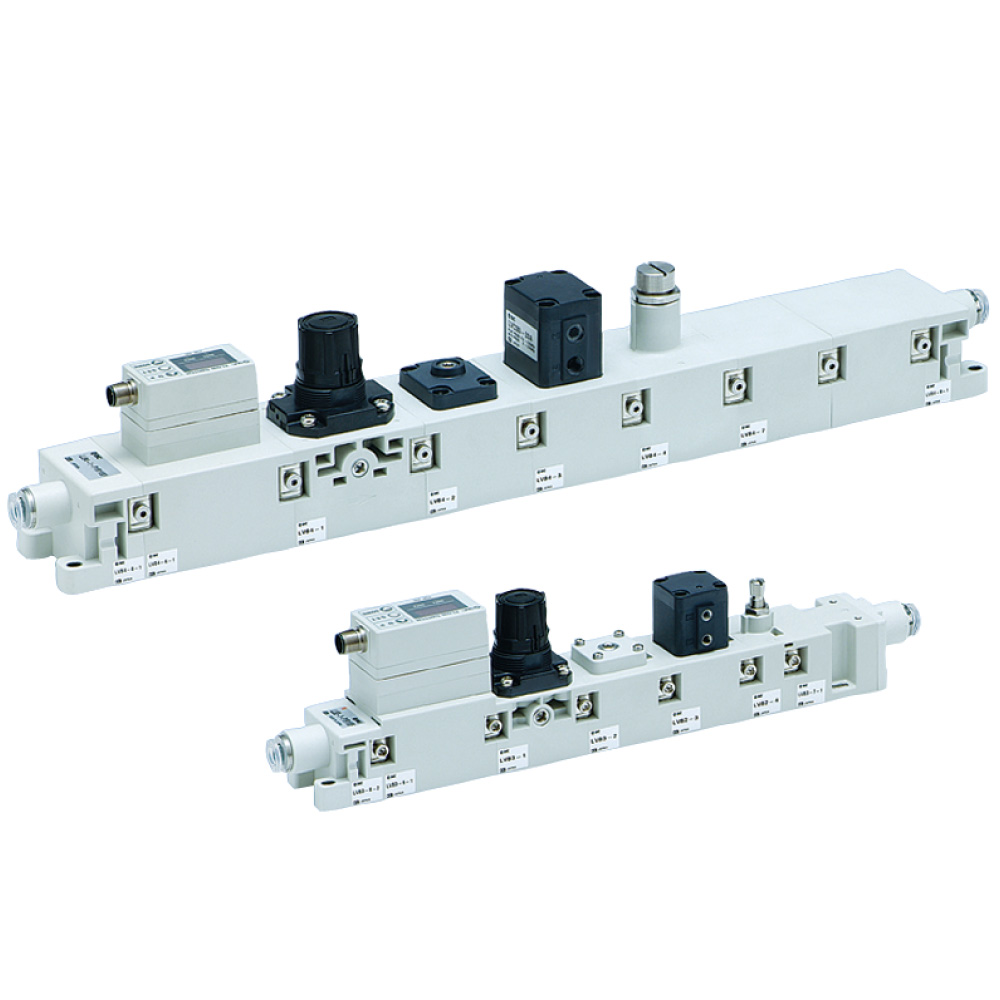

Clean Air Module LLB

Air Preparation Equipment ? Air Preparation FiltersClean Series/Low-Particle Generation ? Compressed Air Cleaning Filter Series

Clean Series/Low-Particle Generation ? Clean Gas Filters/Air Filters

-

?Modularized clean equipment (Reduced piping labor/Space saving)

Makes clean air easily available

?Nominal filtration rating: 0.01 μm (Filtration efficiency: 99.99%)

?Wetted parts: Grease-free, Silicone-free

?Assembled in a clean room, Shipped and packed in double packaging

?24 combinations are available.

Note) Inlet air conditions ISO 8573-1 Quality grade: Equivalent to 1.4.1 to 1.6.1

Safety Instructions Air Preparation Equipment/Precautions Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

| Series | Fluid | Set pressure | Flow range L/min (ANR) |

|---|---|---|---|

| LLB3 | Clean air N2 gas Note) | 0.05 to 0.4 MPa | 5 to 100 |

| LLB4 | Clean air N2 gas Note) | 0.05 to 0.4 MPa | 50 to 500 |